Relationship Between Control Limits And Specification Limits

Control limits are completely unrelated from specification limits which are basically the VOC however specification limits are normally not in our control but control limits can clearly be set as they are the result of our production process. Specification limits are determined externally for example by customers orexample by customers or designers.

Statistical Process Control Spc Tutorial

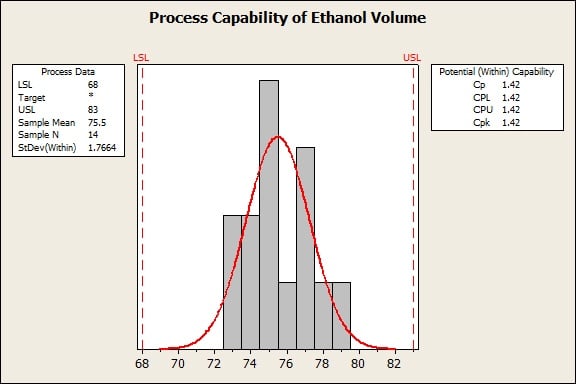

As demonstrated in the given Graph.

Relationship between control limits and specification limits. The differences between specification limits and control limits have been widely discussed since Walter Shewhart of Western Electric invented the process control chart in the mid-1920s. PowToon is a free. A Yes Specification limits Control limits B Yes Control limitsSpecification limits2.

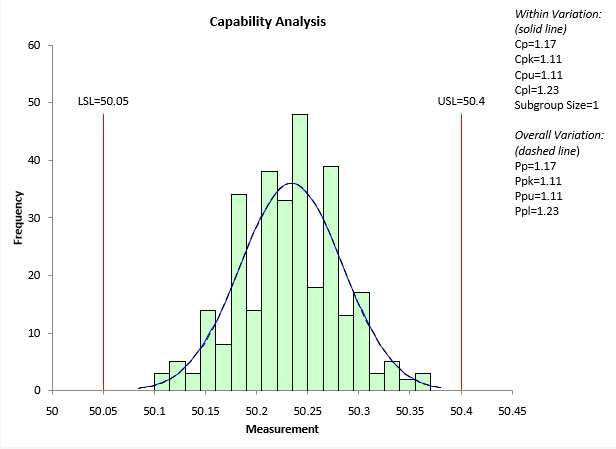

The higher the value of Cp the better the process. Control limits show the range of variability we expect from the process and are based on actual process output. An X-bar chart and an Individual measurements chart will have different limits.

Limits without regulatory commitment. However these differences seem to be poorly understood at all levels at many organizations and even among some quality professionals. On behalf of EBE.

Limits driven by the natural variability of the. Is there any relationship between specification limits and control limits of 𝑥ഥ and 𝑅. Specification limits are normally not in our control but control limits can obviously be set as they are the result of our production process.

Value Added and Non-Value Added Activities in Lean. Relationship Between Control Limit Specification Limit. Limits defined by customers b.

Setting Specifications How and Where to Control Karin Sewerin. Specification limits are chosen in numerous ways. When Control limits exceeds the specification Limit some part of the process will be functioning outside the Specification range.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Cp Cpk Cm Cmk control limits. Pankaj Kumar Apr 24 2019 0 7480.

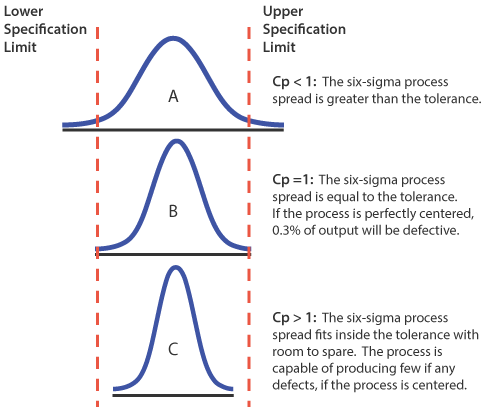

It is the number of times the spread of the process fits into the tolerance width. 14 Is there any relationship between specification limits and control limits of x and R charts. There is no mathematical or sttiti l lti hi bttatistical relationship between the.

Control limits are called the voice of the process. Differences Between Control Limits and Specification Limits The major difference between the control limits and specification limits is the fact that the control limit is the voice. Pankaj Kumar Apr 24 2019 0 10546.

Yes Control limits05 Specification limits 2- Control limits are ___ a. - relationship of product knowledge and process capability. Relation between Control Limit and Specification Limit.

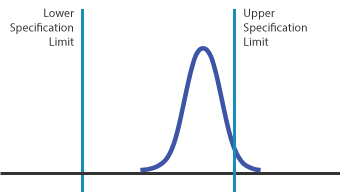

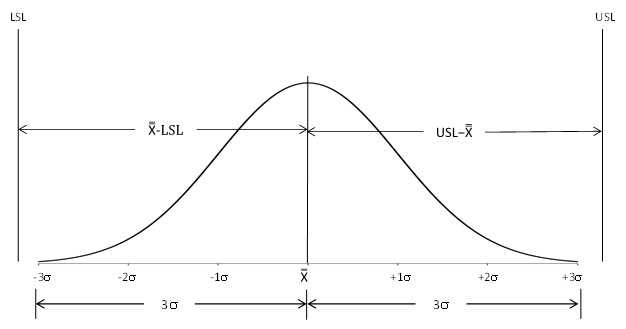

Control charts limit specification limits or targets because of the tendency of those involved with the process eg machine operators to focus on performing to specification when in fact the least-cost course of action is to keep process variation as low as possible. While process variability affects the total process losses the specification limits in no way influence the control limits. The comparison is made by forming the ratio of the spread between the process specifications the specification width to the spread of the process values as measured by 6 process standard deviation units the process width.

Six Mandatory Procedures as required by QMS ISO 9001. Usually there is no relationship whatsoever. Control limits are calculated from process data for a particular control chart.

Control limit values are calculated by the process while the specification limits values are defined by the user. Yes Control limitsSpecification limits2 c. The guidelines for determining whether or not a process is in control apply to its control limits while the guidelines for determing its capability to meet customer needs apply to its specification limits.

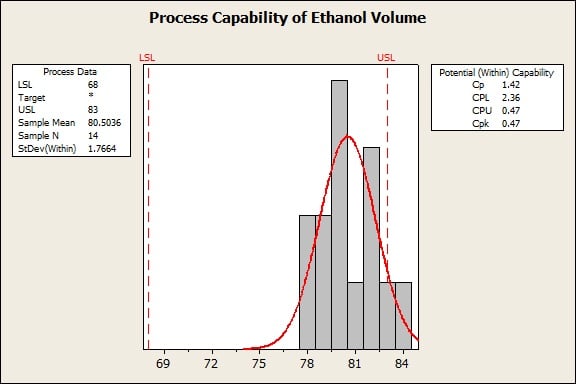

Specification limits are based on the voice of the customer tolerances are provided in order to decide whether a product meets the customers expectations. 1 When Specification Limit Falls between Control Limit. Process capability compares the output of an in-control process to the specification limits by using capability indices.

Pankaj Kumar Apr 24 2019 0 6203. Statistical Process Control SPC Cp capability process The Cp index describes process capability. Effecting changes in control limits is a time consuming process but when undertaken has to take into account specification limits.

Vinay Kumar Apr 24 2019 0 10653. The specification limits are set by the customers needs and are therefore static while the control limits are - 3 sigmas from the mean and are therefore variable. There is no direct relationship between control limits and specification limits.

By saying that I mean that one measure has no effect on the other. Describe the relationship between averages and individuals in terms of specification limits and control limits. If Cp 25 the spread of the process fits 2½ times into the tolerance width while Cp 1 means that the spread is equal to the tolerance width.

Attempting to make a process whose natural centre is not the same as the target perform to target specification increases process. Control limits are derived from natural process variability or the natural tolerance limits of a process.

A Guide To Process Capability Cp Cpk And Process Performance Pp Ppk 1factory

Difference Between Control Limits And Specification Limits Change Management How To Find Out Control

Specification Limits In Capability Analysis Minitab

Process Capability Quality One

Specification Limits In Capability Analysis Minitab

Process Capability Part 2 Bpi Consulting

Process Capability Statistics Cp And Cpk Working Together

Statistical Six Sigma Definition

Specification Limits Proceed With Caution Statistical Process Control Process Control Limits

Statistical Process Control Spc Tutorial

3 4 Per Million Perusing Process Performance Metrics Lean Six Sigma Leadership Training Change Management

Process Capability Statistics Cp And Cpk Working Together

Posting Komentar untuk "Relationship Between Control Limits And Specification Limits"